Nothing contained herein should be construed as an inducement to infringe any patent, and the user is advised to take appropriate steps to be sure that any proposed use of the product will not result in patent infringement. The user should thoroughly test any application before commercialization. The information provided herein relates only to the specific product designated and may not be applicable when such product is used in combination with other materials or in any process. NO WARRANTY OF FITNESS FOR ANY PARTICULAR PURPOSE, WARRANTY OR MERCHANTABILITY, OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED, IS MADE CONCERNING THE GOODS DESCRIBED OR THE INFORMATION PROVIDED HEREIN. Since the conditions and methods of use of the product and of the information referred to herein are beyond our control, Arkema expressly disclaims any and all liability. The statements, technical information and recommendations obtained herein are believed to be accurate as of the date they were published.

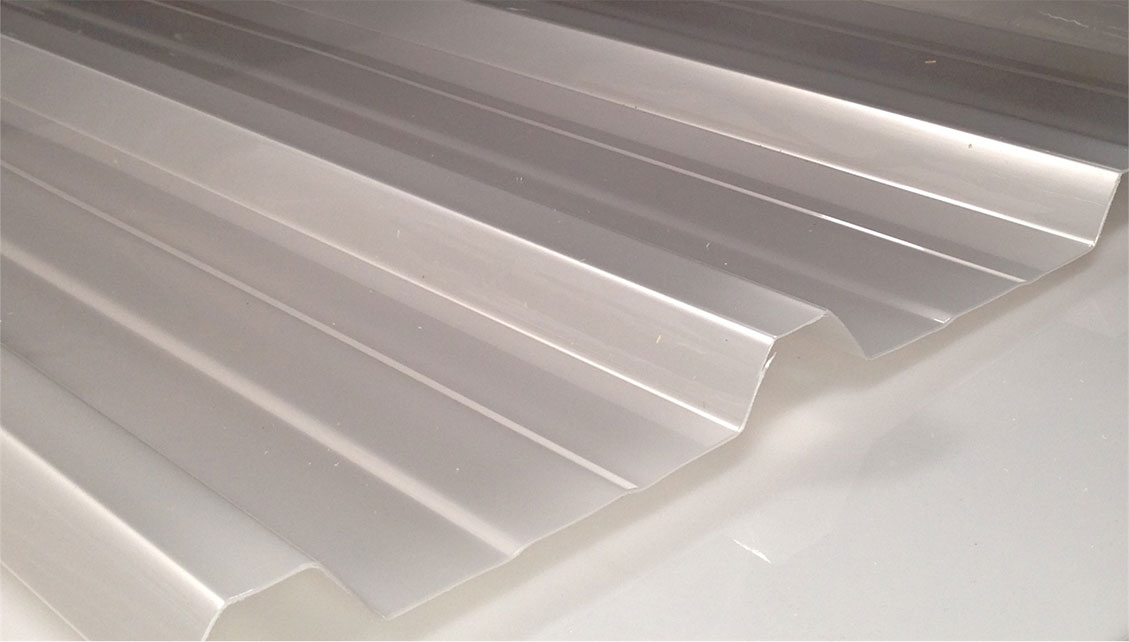

#POLYCARBONATE SHEETS WINDOWS#

Tuffak ® SHEET: U-VALUES (BTU/HR/SQ.FT/F) FOR VERTICAL WINDOWS For pure machining material, there is also compression molded machine grade polycarbonate.

In thicknesses from 0.375" to 2.000" thick - and even thicker on special order. For privacy panels and dividers, we offer textured polycarbonate sheet.įor the most precise engineering applications, we offer a compression molded window grade polycarbonate (either Westlake Plastics Zelux W brand, or Makrolon® from Sheffield Plastics). For various applications we have black and white colored polycarbonate sheet.įor special applications, you can order mirrored polycarbonate sheet - a mirror that will not break (think of uses in correctional facilities). There are limited bronze and grays in transparent colored polycarbonate sheet, and for signs, translucent colored polycarbonate sheet. A wide range of clear Lexan™ polycarbonate sheet hard-coated 1 or 2 side abrasion resistant polycarbonate sheet, known as MR10, SL10, and CM. You should not be able to differentiate between Lexan™ 9034 and Tuffak A for the mechanical, physical and weathering properties of these two sheet products are similar.ĮPlastics® sells a wide range of Lexan™, Makrolon®, and Tuffak® brand polycarbonate sheets and panels. Both of these sheet products are extruded from UVA stabilized polycarbonate resin. Makrolon® GP (in thicknesses from 0.060" thru 0.500") is an equivalent product to General Electric's Lexan™ 9034. Applications include schools, public buildings, and transportation centers. Makrolon® 15 polycarbonate sheet also offers a significant reduction in maintenance cost over its life cycle versus that of other glazing materials. Its improved glazing durability and unsurpassed impact resistance, along with enhanced insulating properties and significant weight reduction, makes Makrolon® 15 clearly the right choice for your glazing applications. Backed by a limited 15 year warranty, this product incorporates Makshield® innovative technology to achieve enhanced performance. NEW - Makrolon® 15 abrasion resistant polycarbonate sheets offer superior long-term weather ability, optical clarity, and vandalism protection. The Poisson's ratio for Lexan™ glass polycarbonate is 0.37-0.38

* GE Lexan™ 5109 is equivalent to the Makrolon™ K-09 Bronze Transparent. * GE Lexan™ 713 is equivalent to the Makrolon™ i-30 Light Gray Transparent. * GE Lexan™ 112 is equivalent to the Makrolon™ GP Clear * GE Lexan™ 9034 is equivalent to Makrolon™ GP We can cut your 4' x 8' Lexan™ polycarbonate panels to exact sizes or ship in bulk. We are an authorized distributor for Tuffak® & Makrolon® polycarbonate sheet products and we distribute genuine Lexan™ polycarbonate panels as well as other brands through our relationships with Sabic and other manufacturers. Clear virtually unbreakable polycarbonate panels. Clear Lexan™ sheets, Tuffak®, Makrolon® polycarbonate sheets.

0 kommentar(er)

0 kommentar(er)